Jewelry laser welding machine laser welder

This welder is specially developed for laser welding of jewelry used in perforating and spot welding of gold and silver jewelry. The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage,it is widely used in the process of gold and silver jewelry and welding of mini and small part.

Features:

1. Ceramic converging cavity is imported from UK. Good performace of corrosion resistant and high temperature resistant, and has 8-10 years service life. The life of xenon lamp is: Max 5 million times.

- Able to work for 24 hours continuously; stable performance; one year warranty;

Human-based design accords with ergonomics, avoiding fatigue after long time working.

- Widely used in jewelry accessories, electronic components, glasses clocks and watches, hardware, precision equipment, medical equipment, auto parts, gifts and crafts, etc.

Working Principle:

Laser spot welding is to use high energy laser pulse to heat the material in a tiny zone, the energy of laser radiation spread into the internal of the material by heat conduction, after the material melted, it will form a particular pool. Laser spot welding machine can weld the same or similar material together.

OBSERVATION SYSTEM

Microscope magnification: 17.5X. + Word cursor center and the laserspot alignment (user adjustable). With high-speed electronic filter protection device to protect the operator eyes laser injury, relieve the operator eye fatigue,improve work efficiency, the installation of high-definition CCD surveillance systemsare available upon request.

CONTROLLING SYSTEM

An exclusive miniature industrial computer that contains the full functionality of an ordinary computer, its stability and anti-interference ability is far better than the industry products.

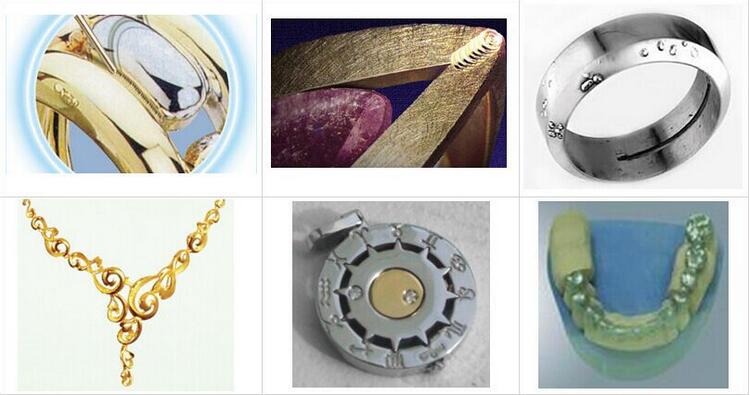

Jewelry laser welding sample

Packaging & Shipping

1.Air or Sea shipping.

2.Equipment will be packed into the standard wooden cartons, suitable for vessel or air transport, and marked the universal label, shipping marks etc.

Our Services

(1) Warranty and Service included:

a. Hardware: 1 year on all parts and labor;

b. Software: whole life on update for free.

c. Maintenance and technological support: whole life.

(2) Training:

a. 3–4 days free training for the whole system in Seller’s company.

b. If customer needs our technician give the training abroad, the customer need pay for the transportation and accommodation fees of engineer;