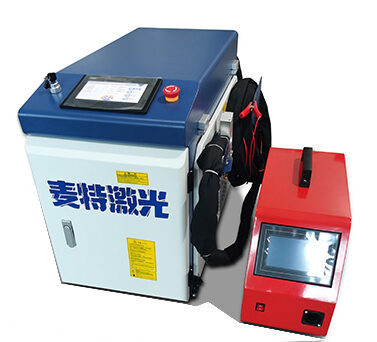

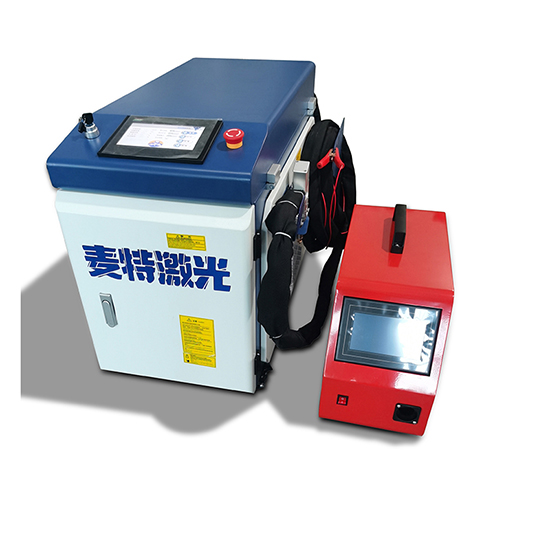

Hand-held Fiber Laser Welding Machine

Hand-held Fiber Laser Welding Machine

Hand-held Fiber Laser Welding Machine

welding stainless steel, metal, brass, aluminum

Weld is exquisite and simple to operate

Power: 1000W 1500W 2000W

- Handheld laser welder speed is 4-10 times faster than the traditional TIG/MIG welding

- Easy to operate, unskilled operator can also weld products beautifully

- Can weld metal products of different materials and thicknesses

- Low welding heat, no deformation of the workplace

- Smooth and beautiful, which reduces the subsequent grinding process and saves time and cost by laser welder

PRODUCT PARAMETERS :

| Model | MAT-HW1000s | MAT-HW1500s | MAT-HW2000s | |

| Laser Output Power | 1,000 Watt | 1,500 Watt | 2, 000 Watt | |

| Welding Depth |

Stainless steel | 0.3-3mm | 0.3-5mm | 0.3-6mm |

| Welding Depth |

Metal | 0.3-3mm | 0.3-5mm | 0.3-6mm |

| Welding Depth |

Brass | 0.3-2mm | 0.3-3mm | 0.3-4mm |

| Welding Depth |

Aluminum | 0.3-2mm | 0.3-3mm | 0.3-4mm |

| Laser wobble width | 0-5mm adjustable | 0-5mm adjustable | 0-5mm adjustable | |

| Feeding Wire Dia | 0.8/1.0/1.2/1.6mm | 0.8/1.0/1.2/1.6mm | 0.8/1.0/1.2/1.6mm | |

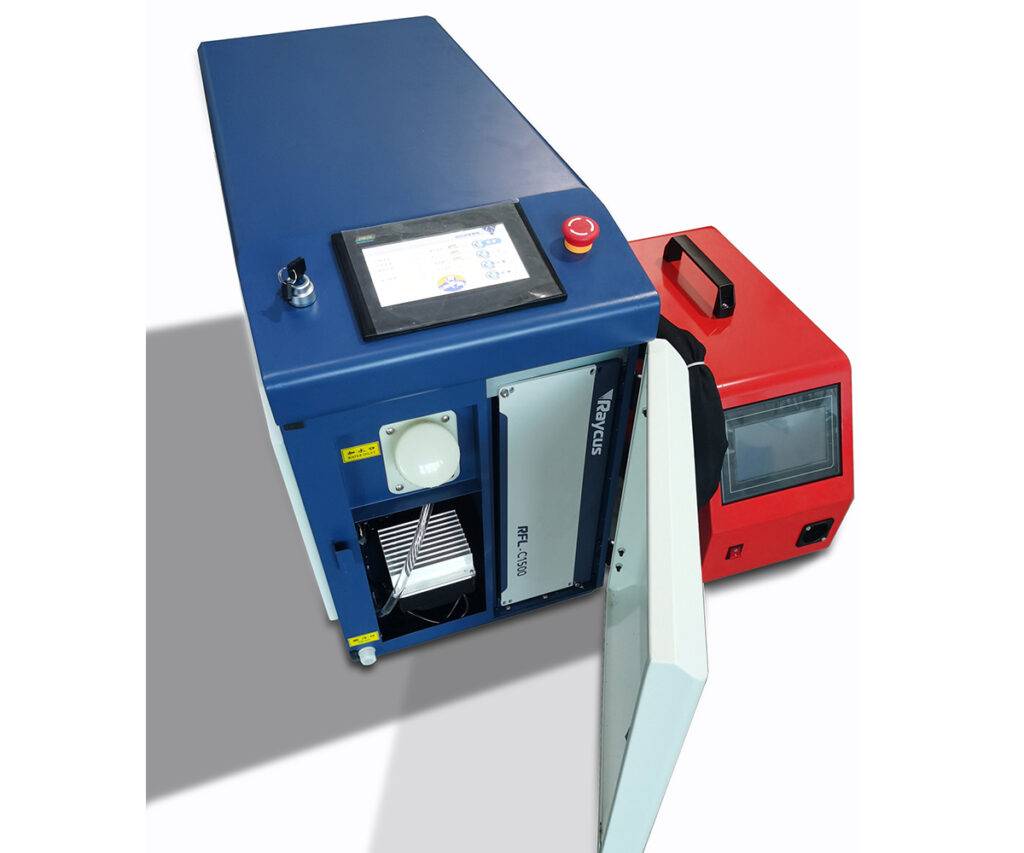

| Laser Source | Raycus/Max | Raycus/Max | Raycus/Max | |

| Fiber Length | 10m | 10m | 10m | |

| Laser Wavelength | 1064nm | 1064nm | 1064nm | |

| Power Consumed | <4KW | <6KW | <8KW | |

| Temperature | 5℃ — 40℃ | 5℃ — 40℃ | 5℃ — 40℃ | |

| Electricity Demand | 220V 50Hz/60Hz | 220V 50Hz/60Hz | 380V 50Hz/60Hz | |

| Protecting Gas | Ar,N2, CO2 | Ar,N2, CO2 | Ar,N2, CO2 | |

| Cooling Way | Built-in water cooling | Built-in water cooling | Built-in water cooling | |

Compare with Traditional Welding

Hand-held Laser Welding

Unskilled worker can get started in 10 minutes,The welding speed is 4-10 times that of traditional welding, saving 3-5 professional welder concentrated energy, low thermal deformation, beautiful welding seam, deep penetration, high strength, can weld thin materials.Can be welded by filler wire, or welded without wire.

Traditional Welding

High professional and technical requirements, high wages for workers, occupational diseases, large body injuries, slow welding speed, low efficiency, large heat influence and easy deformation, thick and irregular welds, requiring secondary polishing, large limitations, and can not weld too thin materials.

| Traditional welding | Handheld Laser welding machine | |

| Welding speed | Common | 4-10x faster |

| Heat Affected zone | large | small |

| Deformation | large | small |

| Bond strength with base material | Common | Excellent |

| Subsequent processing | Polish | No or very little polish |

| Consumables | many | Little |

| Operation difficulty | Complicate | Simple |

| Operator safety | Not safe | Safe |

| Impact on the environment | Pollutional | Enviromental |

| Welding fault tolerance | Good | Good |

| Pendular welding | No | yes |

| Adjustable spot width | No | Yes |

| Welding quality contrast | Bad | Excellent |

Photo show:

Machine Advantage:

Hand-held laser welding machine, using the latest generation fiber laser, has higher electro-optic conversion efficiency, better beam quality, less maintenance cost and higher welding speed than the previous YAG optical fiber transmission welding.Equipped with self-developed WOBBLE oscillating welding head to fill the gap of hand-held welding in laser equipment industry, the internal design is smart, good interactive control system, expanded the tolerance of processing parts and weld width, solved the disadvantages of small laser welding spot, the welding seam forming is better, the shape is light, adopted the body engineering design method, the advanced extremely simple oscillating structure, presents the circular spot, it is deeper, more reliable, lighter and more comfortable than other welding heads on the market which rely on the deflection swing of vibration mirror.

With multiple safety alarms, automatic light locking after moving the starting parts, high safety, beautiful welding seam, fast speed, no consumable material, no welding mark, no color change, no post-grinding, can be configured with a variety of angle nozzles to meet the welding requirements of different products.

The hand-held optical fiber laser welding machine aims at the laser welding of long distance and large workpieces . The heat affected area is small during welding, which will not cause the deformation, blackening and trace problems on the back side.There is no depression on the convex part of solution tank and matrix.Perfect replacement for traditional argon arc welding, welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials.

Application industry:

It is widely used in the complex and irregular welding process of kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel house, advertisement word etc

Welding samples:

Advantages :

A. The machine is easy to handle and don’t need the professional welder.

B. With 10m fiber wire, Can weld long-distance and large-area parts.

C. High quality and very stable: With a long lifespan to 100000 hours and free of maintenance.

D. High efficiency: more than 5 times of the TIG welding with low energy consumption.

E. Various welding process: jam welding, seal welding, spot welding, stitch welding and overlap welding F. Inappreciable heat-affected zone, little deformation good-looking smoothly welding seam.

G. Little remedial work after welding, high-quality of welding line, precise control of positioning accuracy, small spot focus and automated welding

H. Low cost, no consumables, energy saving and environment protection.

I. With the auto wire feeding, IT cover more wide gap and enlarge the application.

OUR SERVICE :

1. 1 year Guarantee for the whole machine.

2. 24 hours on line service

3. 3-7 days lead time

4. We will provide the Instruction Book, Operational manual and Training Video

5. Provide technical support for the whole lifetime on line

6. TT payment

7. Shipping By air, DHL, Sea.