Energy feedback fiber transfer yag spot laser welding machine

Energy feedback fiber transfer yag spot laser welding machine

Energy feedback fiber transfer yag spot laser welding machine

Automatic table welding

Automatic scanner welding

Introductions:

Adopting the Pulsed xenon lamp-pumped Nd:YAG,1064nm infrared laser of the laser crystal output,arbitrary waveform real-time control of laser power feedback technology,the Laser welding system of our company ensures that the laser power waveform in working condition with good stability and reproducibility.

Products of laser power from 25W to 500W, covering in small, large, power system, basically meet the demand for precision welding of various industries. Mainly for the welding of thin-walled materials and precision parts our products can realize spot welding, butt welding, stitch welding and seal welding. With features of depth width ratio, small weld width ,small heat-affected zone , small deformation, high welding speed, smooth weld, beautiful appearance, high welding quality, no pores, size-small focal spot, as well as precise positioning , WF series optical fiber laser welding machine can be accurately controlled ,and easily realize automatic optical fiber transmission .They are widely used in battery industry, IT industry, electronics, optical communications industry, sensor industry, hardware industry, the auto parts industry, mold repair welding industry, jewelry industry, glasses industry, porcelain teeth, the solar energy industry, and electric industry.

According to product processing needs, you can select the following supporting table system

– Galvanometer type welding table

– Two – Four axis welding table

– Robotic welding table

(optional)

Features:

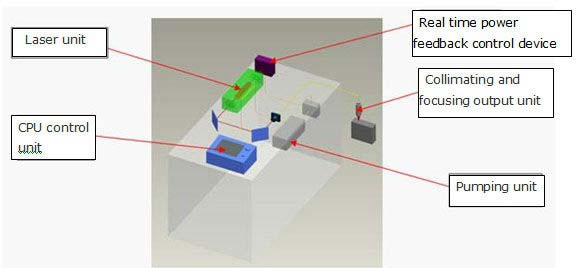

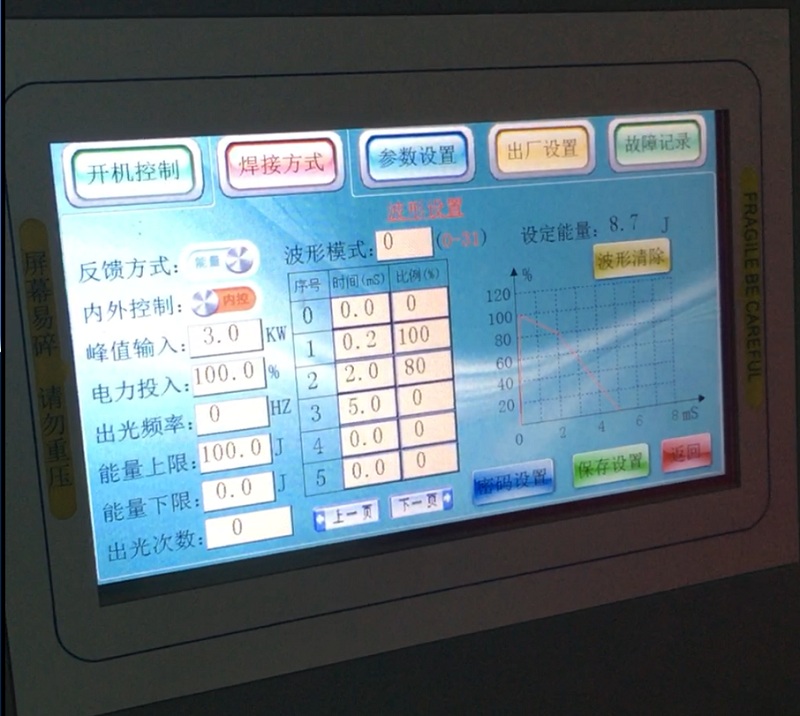

Energy negative feedback

The working principle of Energy negative feedback is to gain an energy detection device at the output end of the laser as to detect laser energy size. Real-time feedback of the signal to the control side is then compared with the energy set theory, forming a closed loop control system to achieve the purpose of accurate control of the laser energy output as follow:

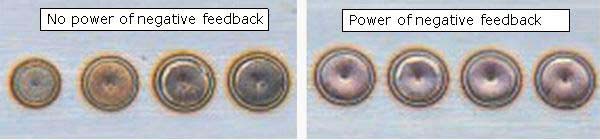

The negative energy feedback technology allows the laser output energy with good repeatability, simply put, is to ensure that each output of the laser energy stability, which can be effective in reducing the defect rate of the product.

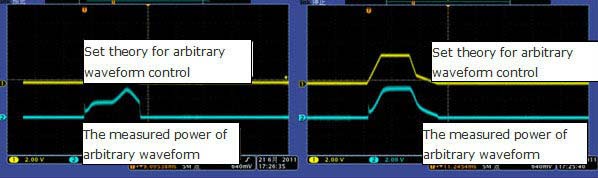

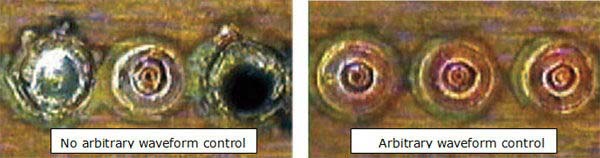

Output waveform can be any set of welder materials, shape, etc.

Specific workpiece welder process, according to the shape and materials of the work, change the output waveform of the laser energy can greatly improve the welder quality, and even some traditional laser welder problems can be solved by changing the laser output waveform.

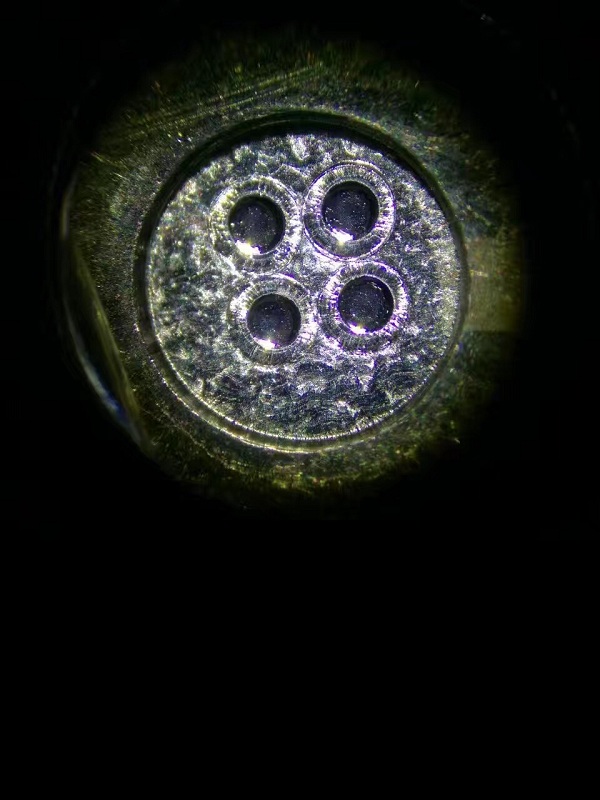

The laser can achieve multi-fiber output at the same time

Compared with traditional hard light output, you can increase the freedom of processing, process multi-beam and multi-bit at the same time, providing the conditions for more precise welder.

Welding or welder timeshare can be realized through the energy of light or time light splitting.

Rich in the I / O interface, users can easily control the welder machine

The key components are imported, to ensure the quality of the product

Applications

Mainly for the welding of thin-walled materials and precision parts our products can realize spot welding, butt welding, stitch welding and seal welding. With features of depth width ratio, small weld width ,small heat-affected zone , small deformation, high welding speed, smooth weld, beautiful appearance, high welding quality, no pores, size-small focal spot, as well as precise positioning , WF series optical fiber laser welding machine can be accurately controlled ,and easily realize automatic optical fiber transmission .They are widely used in battery industry, IT industry, electronics, optical communications industry, sensor industry, hardware industry, the auto parts industry, mold repair welding industry, jewelry industry, glasses industry, porcelain teeth, the solar energy industry, and electric industry.

Laser Welding System Mat-W150H

| Model | MAT-150WH Single Fiber Output (Double Fiber Output optional) |

| Laser Wavelength | 1064nm |

| Max Laser Power | 200W |

| Max Pusle Energy | 70J |

| Max Peak Power | 7KW |

| Pusle Width | 0.1-20ms |

| Pusle Repeat Frequency | 1—100HZ |

| Welding Penetraction(SS 304) | 2.0mm |

| Welding Penetraction(CS) | 2.0mm |

| Welding Penetraction(Pure Aluminum) | 1.0mm |

| Welding Penetraction(red copper) | 0.5mm |

| Welding Penetraction(brass) | 0.5mm |

| Welding Penetraction(nickel) | 1.0mm |

| Laser Allotment Method | Precision Energy Allotment or High Speed Time Allotment |

| Closed-loop feedback Control method | Any Waveform Real-time control Energy Negative Feedback |

| Energy Volatility | <±3% |

| Number of Laser Allotment Output | ≤2 |

| Positioning method | Red ray(CCD optional) |

| Cooling Method | Water cooling machine |

| Machine power | 8KW |

| Eletricity Requirements | AC380V±15% 50/60Hz |

| Internal Recycal system | Epoxy Filtraction(Standard Pump 50HZ, 60HZ optional) |

| Machine size | 1250*550*1000mm |

Laser Welding System Mat-W300H

| Model | MAT-300WH Single Fiber Output (Double Fiber Output optional) |

| Laser Wavelength | 1064nm |

| Max Laser Power | 450W |

| Max Pusle Energy | 100J |

| Max Peak Power | 8KW |

| Pusle Width | 0.1-20ms |

| Pusle Repeat Frequency | 1—100HZ |

| Welding Penetraction(SS 304) | 2.0mm |

| Welding Penetraction(CS) | 2.0mm |

| Welding Penetraction(Pure Aluminum) | 2.0mm |

| Welding Penetraction(red copper) | 1.0mm |

| Welding Penetraction(brass) | 1.0mm |

| Welding Penetraction(nickel) | 2.0mm |

| Laser Allotment Method | Precision Energy Allotment or High Speed Time Allotment |

| Closed-loop feedback Control method | Any Waveform Real-time control Energy Negative Feedback |

| Energy Volatility | <±3% |

| Number of Laser Allotment Output | ≤2 |

| Positioning method | Red ray(CCD optional) |

| Cooling Method | Water cooling machine |

| Machine power | 14KW |

| Eletricity Requirements | AC380V±15% 50/60Hz |

| Internal Recycal system | Epoxy Filtraction(Standard Pump 50HZ, 60HZ optional) |

| Machine size | 1460*660*1080mm |

Laser Welding System Mat-W500H

| Model | MAT-500WH Single Fiber Output (Double Fiber Output optional) |

| Laser Wavelength | 1064nm |

| Max Laser Power | 550W |

| Max Pusle Energy | 120J |

| Max Peak Power | 9KW |

| Pusle Width | 0.1-20ms |

| Pusle Repeat Frequency | 1—100HZ |

| Welding Penetraction(SS 304) | 3.0mm |

| Welding Penetraction(CS) | 2.0mm |

| Welding Penetraction(Pure Aluminum) | 3.0mm |

| Welding Penetraction(red copper) | 2.0mm |

| Welding Penetraction(brass) | 1.5mm |

| Welding Penetraction(nickel) | 2.0mm |

| Laser Allotment Method | Precision Energy Allotment or High Speed Time Allotment |

| Closed-loop feedback Control method | Any Waveform Real-time control Energy Negative Feedback |

| Energy Volatility | <±3% |

| Number of Laser Allotment Output | ≤2 |

| Positioning method | Red ray(CCD optional) |

| Cooling Method | Water cooling machine |

| Machine power | 21KW |

| Eletricity Requirements | AC380V±15% 50/60Hz |

| Internal Recycal system | Epoxy Filtraction(Standard Pump 50HZ, 60HZ optional) |

| Machine size | 1460*660*1150mm |

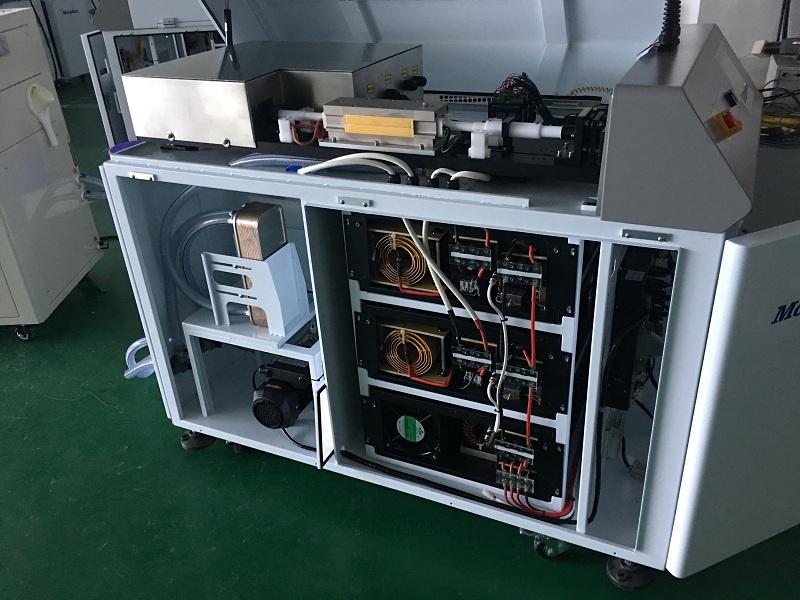

Machine pictures:

Machine Details:

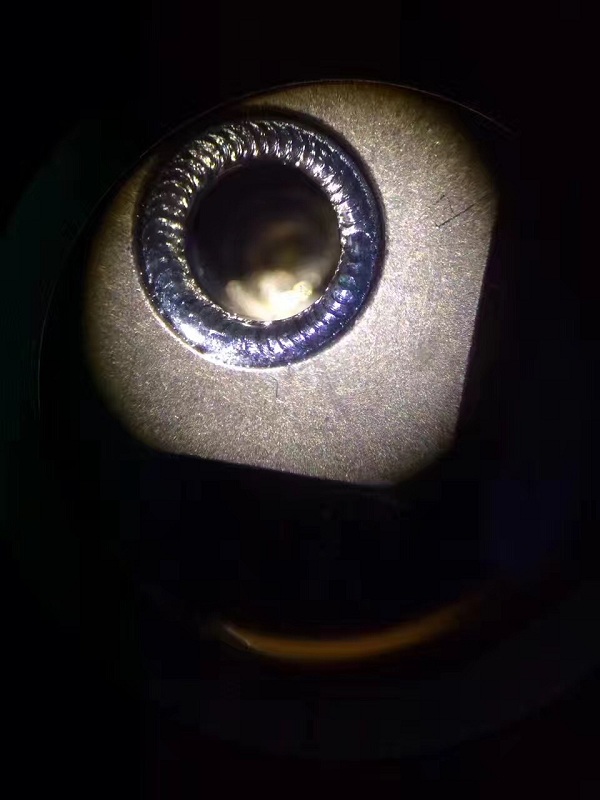

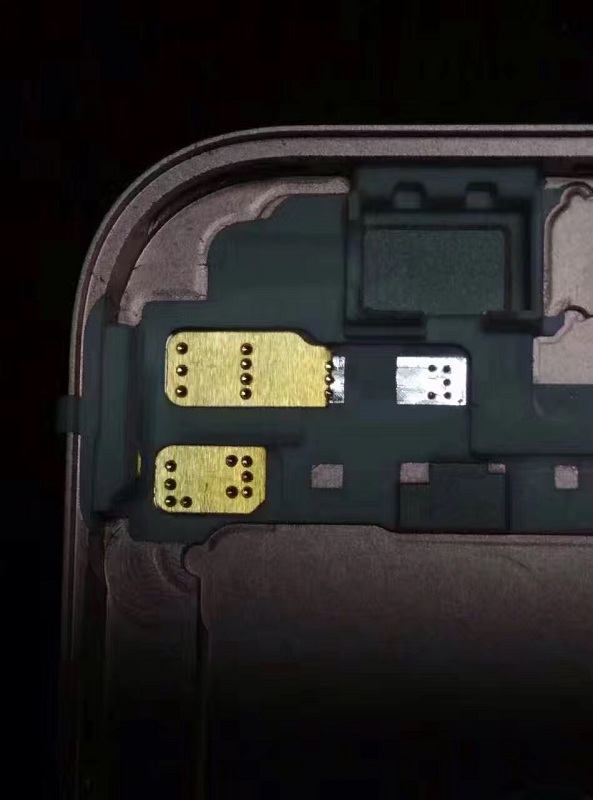

Sample Pictures:

Warranty Services:

One year warranty period (man-made damage is negotiable).

Lifelong maintenance and spare parts supply.

Free design of fixtures as customers required.

Free training for operation staffs.

Free samples of customer provided.